OK all.

As much as I respect most of what Livernoise does, and they are excellent in customer service, etc. This is an area that all Any told you is dead wrong, and here is why. (unless they used some can hooked up wrong...the RX system is the most advanced in crankcase evacuation on the market, but there are a ton of snake oil or wrongly designed cans out there)

So, point by point.

First let me start with my background. I have been doing this for over 40 years and started as a GM factory trained tech in 1974 and have seen most anything in the automotive world as changes in technology and major flops have come and gone. I also do design work that GM has implemented in their advancements in correcting PCV and oil ingestion issues. I do systems for everything from Ford to Ferrari, from classic Maserati's that were the first to implement oil separating cans on their LeMans cars to todays championship drag racing applications.

Myself or my drivers through the years have multiple Divisonal, National, and World Championships in several classes both NHRA & IHRA in stock, super stock, super gas, super comp, top dragster, quick rod, and were one of the dominate teams for years in the Eastern US Big$ Bracket series. I am also a graduate of the Reher Morrison Racing engine building school, and our systems are used exclusively by some of the most respected builders of turbo and supercharged performance builds from the famous Nickey Chicago signature builds (all come with a RX system installed) to IPS turbo charging, SNL, and many more.

We have in the past, and continue to be pioneers in many industry first's (first GM V6 DI top mount supercharger systems, etc.) and when it comes to direct injection and any form of crankcase evacuation, we are among the most respected in the industry.

This is what I have done for longer than many have been alive, and we win or loose in Professional drag racing far to often by thousandths of a second. What we have learned in this lifetime we apply to the real world, and the EcoBoost has serious issues, all caused by a flaw in the PCV system.

So lets start with ANY engine, port injected, carb, or DI. All you ever want in the combustion chamber is air and fuel, and any amount of oil whatsoever has a negative effect in several areas during the combustion process. First, oil does not burn well at all (except 2 stroke oil formulated to mix with gas and burn clean) with the most obvious is the carbon and soot deposits it leaves. It also reduces the usable octane of the fuel and causes detonation (spark knock and spark retard is visible to any tuner logging and engine under load). It also disrupts the burn pattern, and this is critical in the design of the combustion chamber and piston tops (especially in a DI engine). It also reduces the quench areas ability to transfer and absorb heat. Then the deposits left that build up on the piston tops and the exhaust ports reducing the volumetric efficiency that the engineers worked so hard to achieve.

Here is a DI piston and you can see how complex this design is compared to a port injected flat top piston to see just how critical the burn pattern and quench areas are:

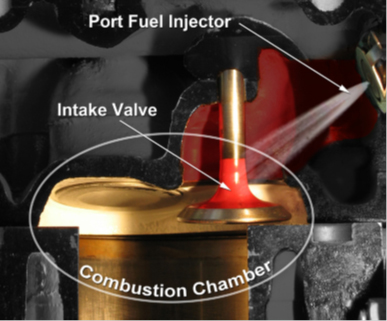

Now lets look at what could possibly be "lubricated" in the intake air charge system and the combustion chamber. There is nothing good about oil in the intake manifold, nothing to lubricate. The valves are lubricated by the oil that is delivered on the valve spring/camshaft/valve train side and there are carefully designed seals to prevent to much from entering. All of this is to an exact science the engineers that designed the engines have arrived at. The lower side of the valves are the tulip and the lower stem. No oil should ever be touching them as it bakes on and forms deposits. With a port injection engine, these deposits are prevented from forming due to the constant shower of fuel from the injectors washing off any of the PCV oil mist from the valves BEFORE it can bake on and form the hard abrasive deposits that are drawn up and wear the valve guides:

This keeps the intake valves clean and retains the shape of the valves and the ports so the engine can flow as designed with no obstructions or vortices created from deposits forming disrupting the complete intake port, valves, and pistons flow.

And that is where direct injection comes in, and the critical need to keep these deposits from forming. Here you can see with direct injection, the fuel can never touch the intake valve as the fuel is introduced directly into the combustion chamber:

Ans since the fuel is not injected (and it is at 1000-3000 PSI depending on the system vs 45-55 PSI for port injection) until the final 20% or so of the compression stroke, there can be no residual fuel brought back from the valve overlap reversion pulses.

This is an un-planned side effect of DI and it must be dealt with. Every auto maker in the world is scrambling to try different techniques, but to date, there is no solution that does not involve the end user draining and disposing of what is trapped.

So, where is any part of the engine benefiting from oil mist (and the sulfuric acid, water, unburnt fuel, and abrasive hydro carbon particles that are part of the PCV vapors)? Absolutely nothing but negative effects.

Now look at the crankcase. Watch this training video to understand what the PCV system does, why it does it, and the damage that an engine will sustain over time if the PCV system is not designed or functioning correctly:

https://www.youtube.com/watch?v=EPIfI9aZHt4Now the Ecoboost has a serious design flaw that only allows evacuation during idle or low throttle. Anytime their is any boost present (app 80% of the operating time) the system closes, and all of these damaging compounds are accumulating and settling into the crankcase and mixing with the engine oil (gas in the oil, water in the oil, high rates of wear and oil contamination) until the crankcase pressure builds enough to force some of this out the clean (fresh) side inlet tube in to the drivers side turbo inlet. Since this is steam and hot gasses, when they hit the CAC (intercooler) they condense into the sludge and gunk that you see when removing the CAC to clean it. It also pushes this mix into the combustion chambers and it there is to much water at one time ingested, then hydro-lock occurs and catastrophic engine damage.

So, lets stop here and again, what part of any of the intake air charge system or any of the moving parts that the intake charge would touch. These are not the inefficient engines of the 50's and 60's, every single moving part will get proper lubrication, and exactly where it needs it, and any parts that should not have any oil on them will experience deposit formation from this build up.

Now lets look at what is in the PCV vapors that he claims are "lubricating" . Oil mist is only part of what makes up these vapors. Sulfuric acid does no metal parts good. Neither does water. The abrasive hard carbon particles certainly dont. Un burnt fuel has no lubricating properties, so this toxic mix could not properly lubricate anything any way, in fact just the opposite.

And further, this is only 15k miles on a Livernoise installed Magnasun supercharger intercooler w/out a proper catchcan installed. This oil has already baked on a residue that has insulated the cooler and reduced it's ability to transfer heat and cool the charge air as well as slowly clogging the fins preventing air from flowing at all eventually.

Then we come to another argument he posted in the past: This involved a claim that these vapors lubricated the top mount superchargers and was good for them. What part I ask? The bearings are all sealed, so no moving parts are touched that need lubrication, and depending on what type blower, most have a constant oil bath from the supercharger lubricant sealed into them. The rotors dont touch, unless oil residue builds up and causes interference and damage as they spin at extremely high rates and the clearance between them is minimal (some have a special coating on the leading edges that wear into each other for as close of tolerances as possible). Then, we have to look at the balance of the rotors. As they travel at such high speeds, 12-14,000 RPM plus, that when this oil residue builds up over time it throws off the balance and THEN we see bearing and shaft failure as well as damage/erosion to the rotors as the touch.

There are over 14,000 RX systems in use out there for over 12 years on every type application there is. If installed correctly, they all do exactly as advertised (as all the testimonials from all support).

Lets look at oil ingestion. The current DI engines still have nearly as bad of intake valve coking and valve guide wear as the early ones. Several patents by Ford, Audi, etc. have different valve timing events and other changes to try and reduce the coking, but to date none have been effective. The EB has such a large amount of water ingestion due to the flaw it actually helps reduce the rate the valves coke with deposits, but the damages caused by all this water in the crankcase, etc. far outweigh the benefits.

Now lets look at how DI engines have improved as far as intake valve coking.

Deposits such as this by 30-50k miles are still the norm:

And even in as little as 12k miles on this 2013:

We can see some progress has been made, but there is a long way to go.

And then there is the buildup of this residue in the ringlands of the pistons. As this builds up the rings stick and are unable to seal properly and excess blow by and oil consumption is the result. Stopping the ingestion can allow them to self-clean and free up again if the issue is not to severe. If it is to severe only a tear down and manual cleaning will correct this.

So, anyone with any questions, ask and be as specific as possible. None of this is opinion that I have posted here, this is all documented fact and reference material is plentiful. You cannot apply opinion and old wives tales to actual engineering and science. And plenty have post pictures of their own intake valves that they performed manual cleanings on to prove it (anyone can easily remove your own intake manifold and see first hand).

No auto maker admits to having the coking issue, yet they advertise how they are correcting it! yet the pictures from techs from all over the world show otherwise. From Audi adding back small port injectors, to GM stating their VVT valve events prevent ANY fuel from touching the valves, to Ford claiming they allow fuel to touch the valves (it does not). So all are scrambling to correct the issues