Hi All,

Lets start at the beginning with all of this, and what the issues are, how the are caused, why most cans on the market allow as much or more oil to pass right through, and what is needed to correct ALL of the shortcomings with the ecoboost. This will include the accumulation of unburnt fuel and water in the crankcase where it dilutes/contaminates the engine oil resulting in increased wear, timing chain failures/stretch, and catastrophic engine failure from hydrolock when a "gulp" of this mixture is pulled from the intercooler all at once.

I also ask everyone to please read, and reread all of this as well as the links to industry papers and photos from techs from every auto maker in the world on these issues, as they are not Ford exclusive, they are with all DI engines, and as of 2014 99% of all gasoline engine produced are now DI. I also am not here to fight, or attack/be attacked. I am sharing over 40 years of experience in the industry, and am happy to list my qualifications and accomplishments if asked. And please understand, RX is not the only manufacturer with a good design, but 99% are only put out there to sell, meet a demand and are VERY poor in function. These companies/people take great offense to anyone laying out all the science and engineering behind what makes a can work, and not work well. and keep in mind, ALL cans (a beer can. mayonnaise jar, etc. will catch oil so it is not what is caught that matters, it is that it is ALL caught and the ingestion stopped).

Lets first address the billet cans (these will have 30 plus name brands including Moroso, etc. but are all the Billet Tech design made in Miami).

This can is beautifull to look at, is made extremely precise, but is one of the least effective on the market due to the following. And I urge anyone with one to unscrew it, remove the mesh from the top chambers, and pull out the media (steel wool) so you can follow all of this as it is simple.

Here is what the RX system traps in 1000 miles or less, this would overfill any of the small cans on the market and this would be not just being ingested in small amounts, but would be ingested in "burps" or "gulps" once a small can has reached its capacity:

Below is the RX monster can (for those with modified ecoboosts) next to a billet tech can. For a can to not allow oil/fluid to be pulled right through it at the rate of flow the PCV system needs to operate, it must be just under 1 qt of capacity to allow the speed of the flow, or velocity to slow to the point the droplets can fall out of suspension. The droplets will be carried through any can, no matter the design due to the Bernoulli effect that creates a low pressure area that will pull liquid into the flow path. Think of a straw placed near some spilled soda on a table. Suck on it and you will pull that liquid right into the flow and up the straw. Now try it with a 3/4" piece of hose....you can't no matter how hard you try. And the PCV flow is many times your ability to do so. So that alone will render any small container not much more effective that a beer can with 2 fittings:

Look at how this design has no designated inlet, or outlet. It has two chambers next to each other with steel wool for a coalescing media (and that works well) so here is what happens. The side used as the inlet will saturate with oil until it begins to form droplets that will be pulled through the mesh, and some will drop to the bottom and be caught, while as much or more is pulled right into the chamber next to it (due to the velocity, or speed of the flow carrying it) into the media against the outlet. Now stop here. Go to the bathroom, take a washcloth and get it wet. Now place it to your mouth and suck on it. What happens? You have sucked water right out of the washcloth the same as the oil is sucked right out of these type designs.

Want to see it in action? Watch the right side app 1/2 way through the video. (this is on a Caddy CTS-V with excess blow-by so it takes no time to begin to see oil:

Moroso TV: Moroso Air/Oil Separator / Catch Can test 2009 Cadillac CTS-V www.moroso.comNote how as the oil saturates the right side (the side they use as the inlet here) it begins to fall to the bottom while in low vacuum/suction, but as soon as the PCV is at max vacuum/suction, that oil is pulled right up the left side and out of the can into the intake air charge. You do NOT want a can that allows oil to pass right through (does not matter that you see oil caught, it is what gets past a design). So this creates a "Placebo" effect for those that have installed them and when they open them, they see oil and figure they have corrected the issue. What has really happened is you have helped make someone $ while only preventing a small part of the real issue you were looking to correct. Want to see more? Place a RX can between any can and the intake manifold and it will catch cas much or more oil/mixture than the primary can so the proof is right in front of you. Other cans that are design and work very well?

The Elite E2, the Apex, and the SMC all are excellent (and direct competitors) that catch most of the oil and will make a difference, but out of the hundreds offered, only these 4-5 are worth installing, and to date, none equal the RX in design and effectiveness (but some are coming close).

Now on to some others:

This is very popular:

has a site tube to see when it is getting full, and is marketed under dozen or so name brands. We cut it apart and we see this:

The vapors enter one fitting and do a U turn out the other. Only the residual vapors that do swirl around drop oil. (almost all cans are a variation of this including the Mishimoto's best that allthough it has filtration, it is designed so the incoming oil laden vapors mix with the other vapors and a good amount still pulls through).

This one is billet, looks great, AND is large enough! But when taken apart, it is just another empty can with 2 fittings attached:

We can post dozens of similar pictures.,...a company that takes a $8-12 Home Depot air compressor unit and charges $100 plus for, etc. there is no shortage of choices, just few that will do the job, and that is so confusing for those not understanding all that is involved.

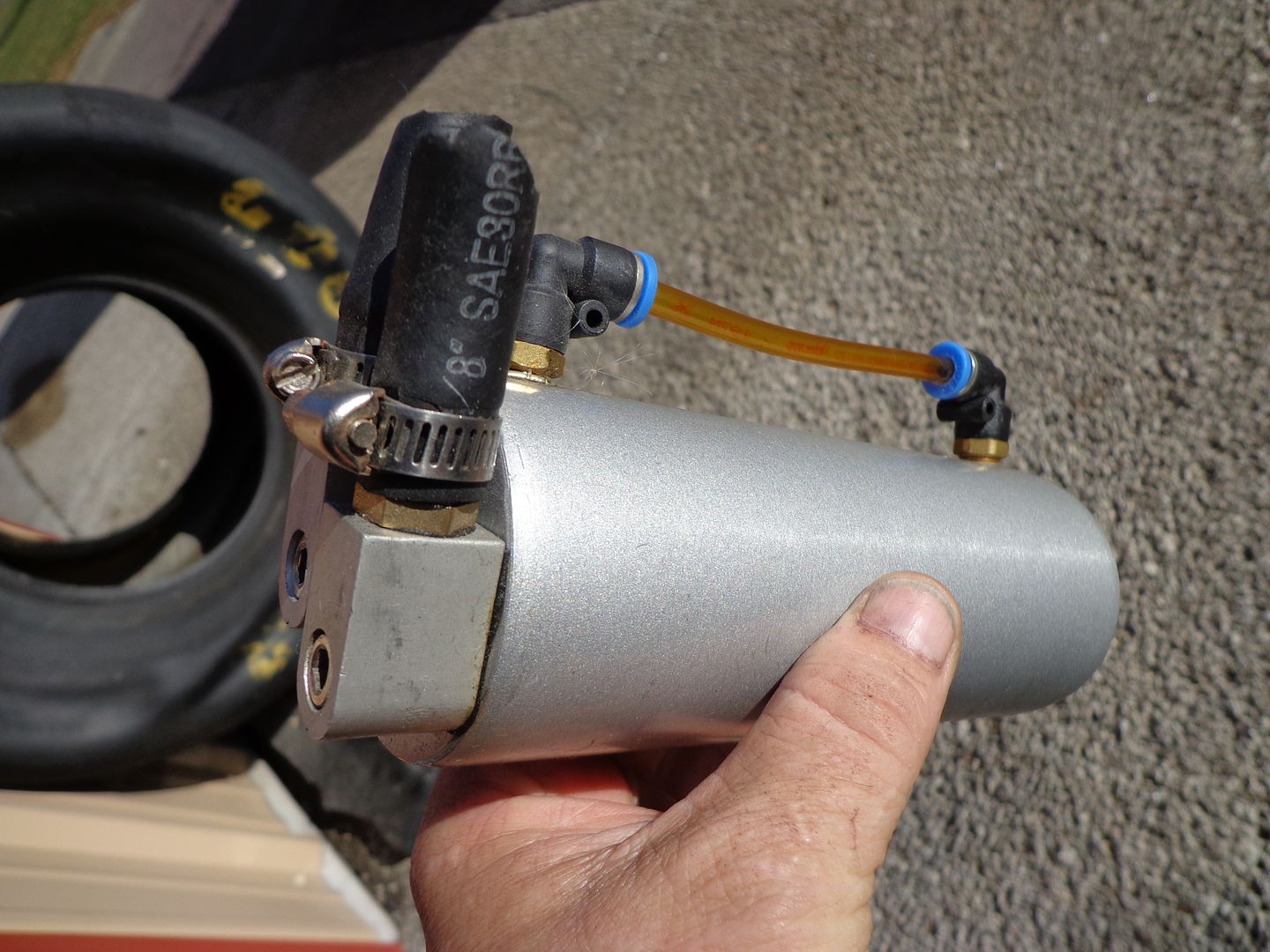

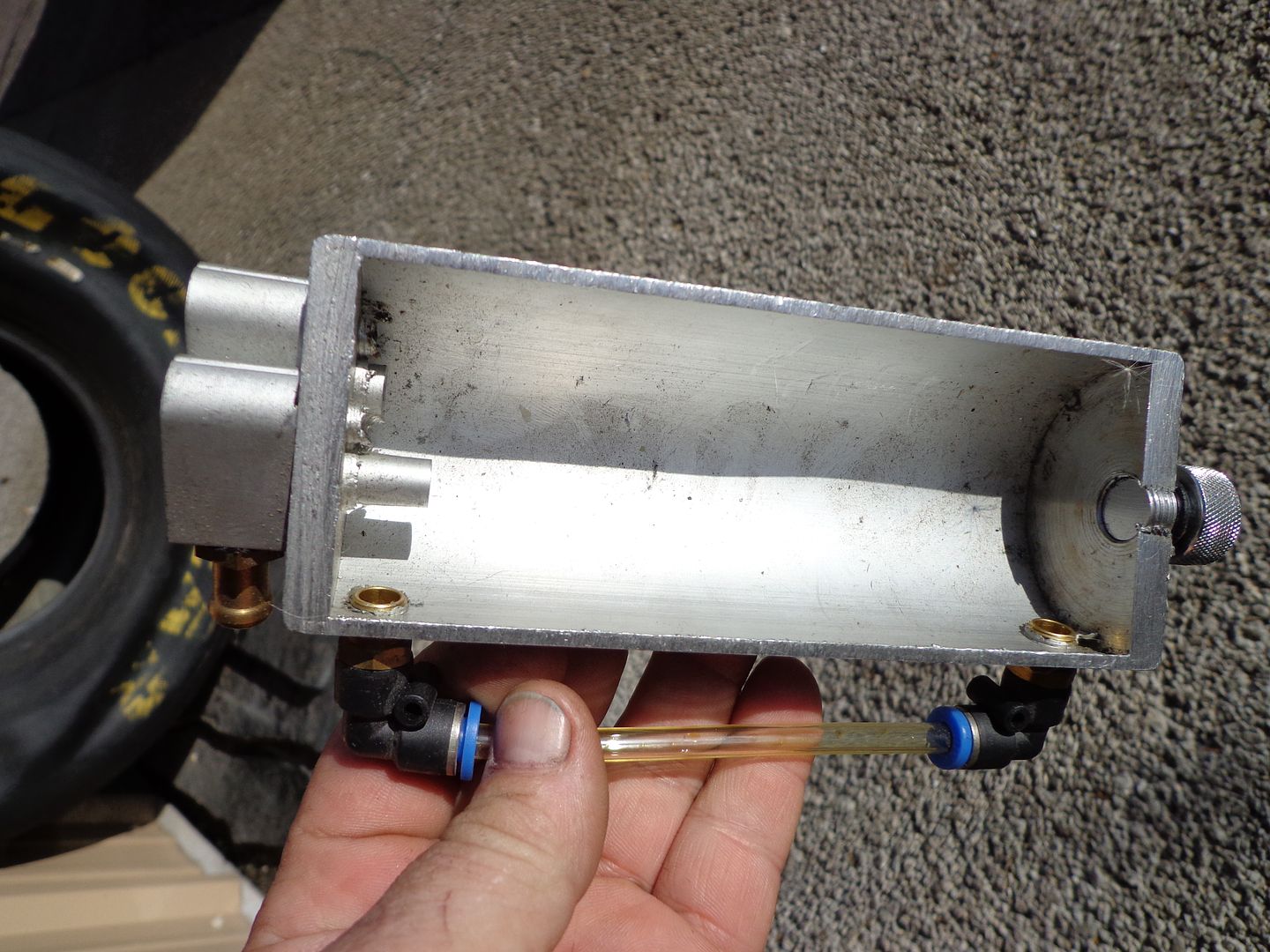

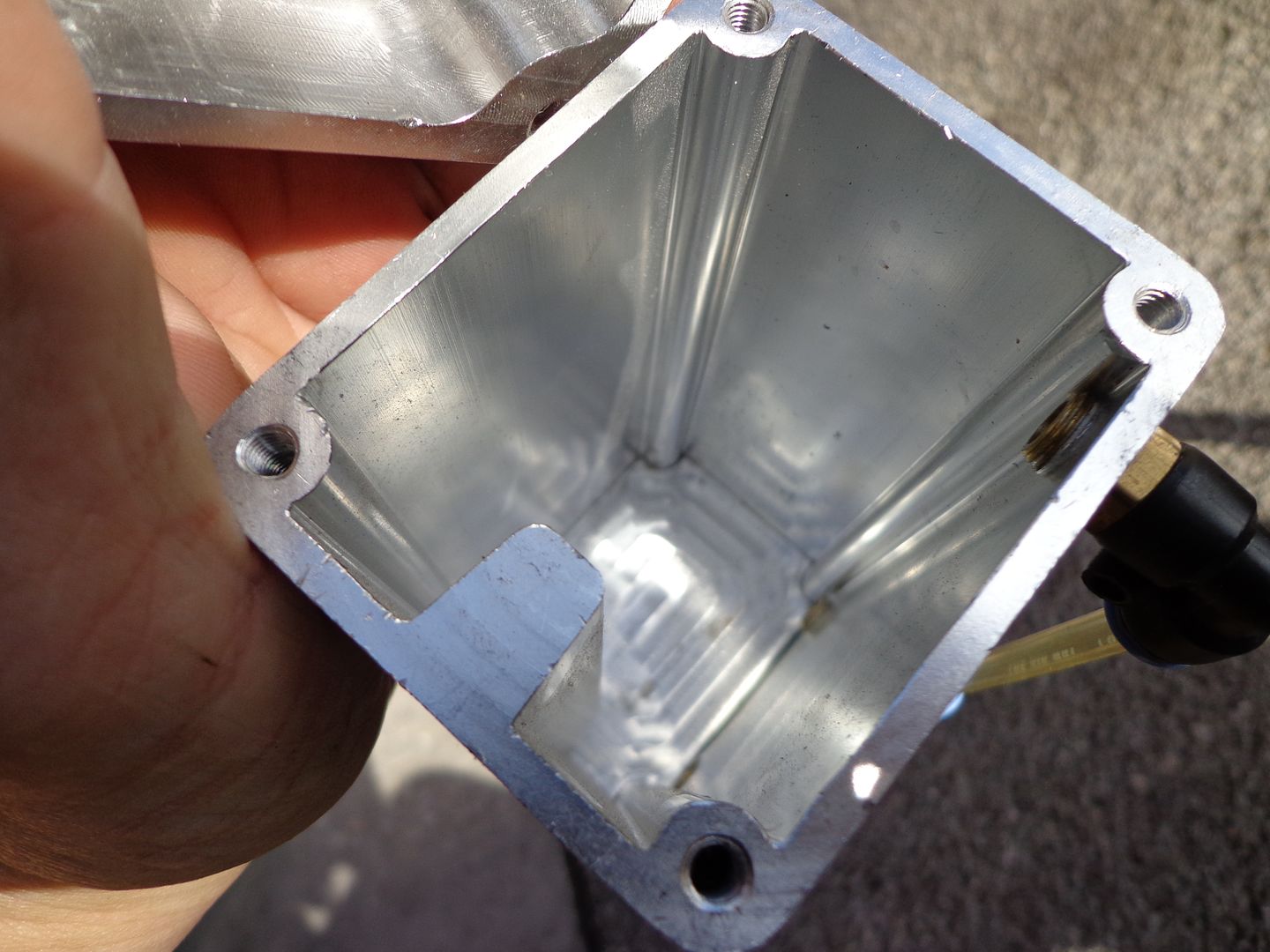

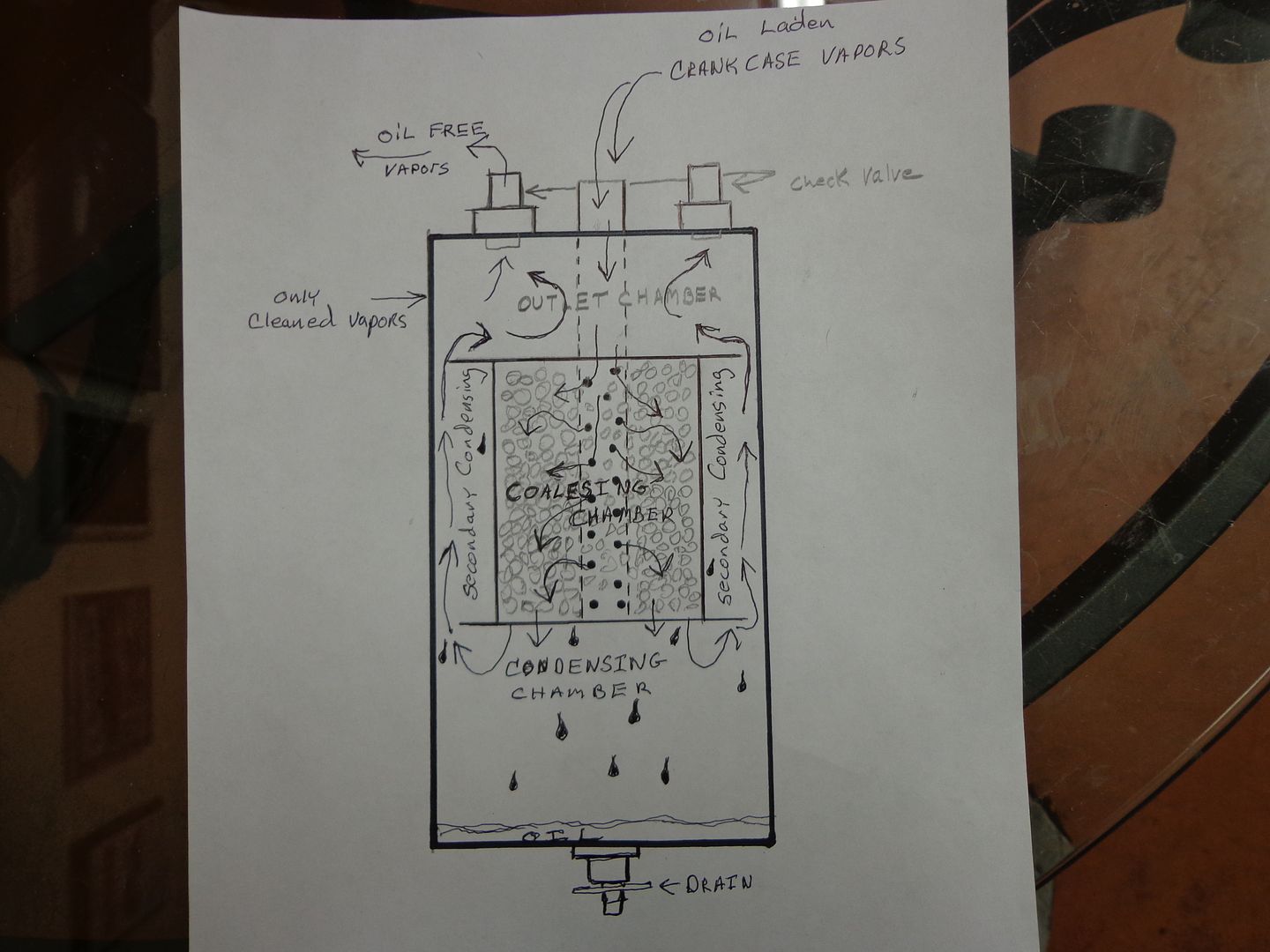

The RX can has 4 separate chambers, 3 separate processes to separate, coalesce, and condense the oil/vaoprs and trap them:

The oil laden vapors enter the center fitting where they travel past the outlet chamber into the coalescing chamber where the dispersion tube is perforated allowing the vapors to evenly travel through all the media. This will trap 90% plus of the oil and other damaging compounds we don't want in the intake air charge. Then the droplets will fall out the bottom of the chamber to collect in the main condensing and collection chamber. The vapors as you will note, are never able to mix with the dirty vapors entering the RX can. No other can keeps them all separated through the entire path through a can. The then are forced between the outer cooling wall of the can as they pass the lower disc baffle. This forces all the vapors to make even contact with the outer surface and any remaining suspended compounds are condensed to droplets and fall to the bottom. The vapors will again slow after passing the lower disc baffle as the secondary condensing chamber will allow further cooling and capture an residual droplets before they again pass the upper disc baffle which again forces all to make contact one final time with the outer cooling wall before the cleaned vapors enter the separate outlet chamber where they the exit either outlet depending on whether in boost or non boost operation.

Now lets see how this applies to the Ford Ecoboost and the issues it has.

First, the ecoboost is one of the most advanced domestic v6's ever released. The design and principals are sound and it has the ability to produce more power, at less weight, and more efficiency than most earlier V8's ever could. It's design and tolerances will allow it to live 300-400k plus miles if cared for and the problematic PCV system is corrected. If not, it can be very problem prone and have a short lifespan due to one weak area, the PCV system.

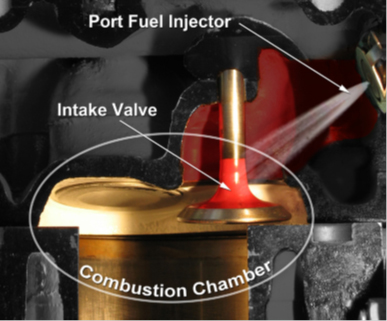

Lets first look at the difference between traditional Port Injection engines that would never see intake valve coking issues as long as a good top tier fuel was used. With a port injection engine the intake valves are always showered in a fuel spray that kept the intake valves clean and deposit free:

Although this kept the intake valves clean, it was not the most efficient way to introduce fuel precisely like the direct injection of today.

Here is a direct injection diagram:

Direct injection introduces the fuel directly into the combustion chamber, and it does so in the final 20-30% of the compression stroke so the fuel is only present for milliseconds. Far less chance of detonation and as it is only during this time there is zero fuel back-flow from reversion pulses. The fuel is also at 2,000-3,000 psi VS 45-55 psi of old, no fuel injectors clogging anymore and the atomization is far better for a more complete and efficient combustion/burn. More power, less displacement, and great economy. In fact the use of expensive top tier fuels now make not difference from the discount brands. This also allows compression ratios of 11.3:1-11.5:1 with out needing race fuel to avoid detonation. Tons of advantages, but one huge draw back (not planned) is the intake valve coking issue as the oil and other compounds ingested as part of the PCV systems function cause rapid buildup on the intake valves gradually reducing the volumetric efficiency of the port/valve design and less power, MPG, etc. is the result. Here is a link to pictures submitted my techs from every auto manufacturer, motorcycle, 4 stroke snowmobile, and 4 stroke outboard to show how widespread this issue is. Please take the time to look closely at these pictures to see how this effects power and fuel economy over time:

http://isearch.avg.com/images?s=sideNav&cmpid=&q=DI+engines+intake+valve+buildup+coking&sap=hp&lang=en&mid=e2d20ddb3e3947d080e43909b45a757f-85d79d8eab41c5fe328337b5f1e509e263b79872&cid=%7bEE610A28-F04D-414F-A607-57AD2D81AD35%7d&v=17.0.0.9&ds=AVG&d=9%2f26%2f2012+6%3a46%3a11+PM&pr=fr&snd=hp&ctc=+&pid=avg&sg=0Now, lets move to ecoboost specific issues. The ecoboost is a twin turbo system, and any time you are pressurizing the intake manifold during boost you cannot allow that pressure to enter the crankcase or blown oil seals, etc. are the results. So to prevent this, turbo applications will have a one way checkvalve in the PCV system that closes while in boost operation.

A properly functioning PCV system will constantly evacuate/flush the damaging combustion byproducts from the crankcase. It does this by clean, filtered fresh air entering one bank of an engine (the fresh, or clean side..in this case the drivers side) where it is flowing through the engine internals and the crankcase where they are sucked out the opposite bank (passenger side on ecoboost) and they are burned in the combustion process and further in the catalytic converters. The problem is today engines rev higher and have overhead cams and timing chains that create a good amount of oil mist/vapor. This is pulled out along with the damaging combustion byproducts and causes the oil coking on the valves, excess carbon deposits and residue in the ringlands that over time cause rings to stick and not seal properly. The rest of the compounds are water. sulfuric acid, abrasive carbon particles, and unburnt fuel (as well as several other hydrocarbons, etc. but these are the main compounds).

Where do these come from?

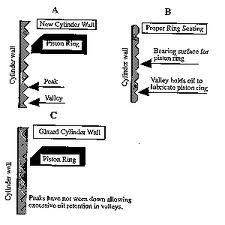

Mainly they are in the blow-by that all engines have, but in the past 10-15 years engines (except aircraft, etc. where safety is more important than inconvenience and ring seating is critical to safety) come prefilled with a synthetic blend or full synthetic. This oil is far to protective to allow the friction needed for the rings to seat, or wear in the the cylinder walls if driven per the owners manual (babied) so after 400-500 miles the cylinder walls will form a hard glaze that prevents any further seating and this brief window has passed. In the old days, engines came prefilled with break-in oil and this allowed enough friction to seat the rings in this short window, but it also required you drive very easy to prevent damage to bearings and journals, etc. So now most drive esy during the first 100 miles and the rings never fully seat allowing excess blow-by and oil consumption.

Here is a good diagram to show this:

So it is important to either drain the factory oil day one and fill with conventional to break in, or drive relatively hard (full accelerations and deceleration's are critical to produce side pressures needed to facilitate ring seating).

And all engines have a certain amount of blow-by, but anytime you are adding static CR or pressure to the combustion process you increase this. So were now back to the ecoboost and its PCV design flaws. The ecoboost will have more unburnt fuel and water as part of the blow-by. Normally this would not be an issue if the PCV system was constatnlty evacuating these but since the ecoboost only evacuates at idel, and easy non-boost operation, everytime the engine transitions to boost the intake manifold vacuum source is closed byt the checkvalve in the passenger side valve cover (PCV valve) and the engine provides NO evac source during boost, so the pressure from the blow-by forces the crankcase vapors (laden with fuel/water/etc.) to reverse direction and seek a release. This is backwards through the drivers side cleanside tube and into the intake side upstream of the drivers side turbo.

All of this concentrated mix of nasty compounds is then ingest by the drivers side turb and porced through the intercooler and then into the intake manifold. In the intercooler this cools and condenses and accumulates as a "slduge" of oil/water/sufuric acid and other compounds. When this accumulates to the point a "gulp" is sucked through, it can casue hydrolock and busted pistooons and bent rods are the result. No matter what happens, you dont want any of this other than the unburnt fuel and some water vapor entering the combustion chamber, and onlu in small steady amounts which is impossible with the OEM design. So as this mix is retained in good amounts in the crankcase instead of evacuated, it accumulates. Every time you shut the engine down and it cools, these compounds will condense and drop into the oil coating internal parts and contaminating the oil reducing it's ability to protect (oil cannot maintain its protective properties if contaminated with water and fuel) so we see timing chain stretch and bearing failures due to this.

Now just adding any catchcan will catch some of this mixture, but it does noting to correct the flaw in evacuation. To do this, we must provide a secondary suction/vacuum source for evacuation during boost as well as non boost operation. To do this we take the intake side of the turbos so the RX system will provide evacuation during non-boost using the intake manifold vacuum. And when the engine transitions into boost, the primary valve will close and the secondary valve opens using the suction side of the turbo pipes to continue the evacuation at a steady rate, and maintaining flow in the correct direct eliminating the intake valve coking, the water/oil ingestion into the intercooler and charge piping, and the cleanside separator (or breather for off-road use) prevents ingestion into the cleanside during that transition from boost to non boost (there will always be a moment of reverse flow during this depending on the level of blow-by).

So now the RX system is trapping all, or nearly all the ingestion from the dirty side, and also prevenmting ingestion into the cleanside by the separator or breather.

Here are some pictures showing this:

RX Dual Check Valve Catch Can and 2013 Ecoboost F150As you can see anyone using any other cans you would exceed the capacity of the small can in 100-200 miles period, and then what happens? This mixture is pulling past those cans and directly into your system.

The RX system stops the unburnt fuel and water accumulation in the oil that is wearing engines out in a fraction of the time, and none of the TSB fixes from Ford cures the issues.

They replace the PCV valve and line to attempt better flow, but do nothing to address the no evacuation during boost. They alsore-program so the engine makes less boost/power and no one wants this.

The RX system cures most all of these issues, but requires weekly drains when below 45* F and monthly in summer months. There is no way to make a maintenance free system as you cannot return this concentration of damaging compounds to the crankcase, it must be disposed of properly.

ALL manufacturers are working on solutions, but there can never be an affordable one that does not require the extra step of draining. That requires a centrifuge based system that can purify and filter the oil such as an industrial system by Alfa Laval or similar ($3000-$100,000 plus) so dont expect the auto makers to solve this...they would rather pretend it does not exist (not a single auto maker acknowledges this is an issue).

I don't have a ton of time to spend on the forums, but I will check in from time to time to answer more questions. Please ask direct questions on any par not clear, and on ANY thing of a technical nature involving engines or related automotive subjects.

Been doing this for over 40 years and designing and engineering products for the aftermarket performance industry as well as some incorporated by the Big 3. Also have spent ages owning, racing, managing professional drag teams with (my drivers or myself) years of Divisional, National, and World Championships in several classes both NHRA & IHRA as well as starting as a GM tech in 1974. (if anyone wants a more comprehensive list of qualifications just ask....some are offended when I volunteer them so that is not my intent).

Tracy & Team RX