Excellent question. While most cans are empty cans with nothing inside, the few that do have baffles, etc. still allow the incoming oil laden vapors to mix with the outgoing, and then most are far to small in internal volume (2-3 oz's) so the flow can never slow enough to prevent oil pull through. RX is nearly 1 qt in internal size.

No can is designed like the RX.

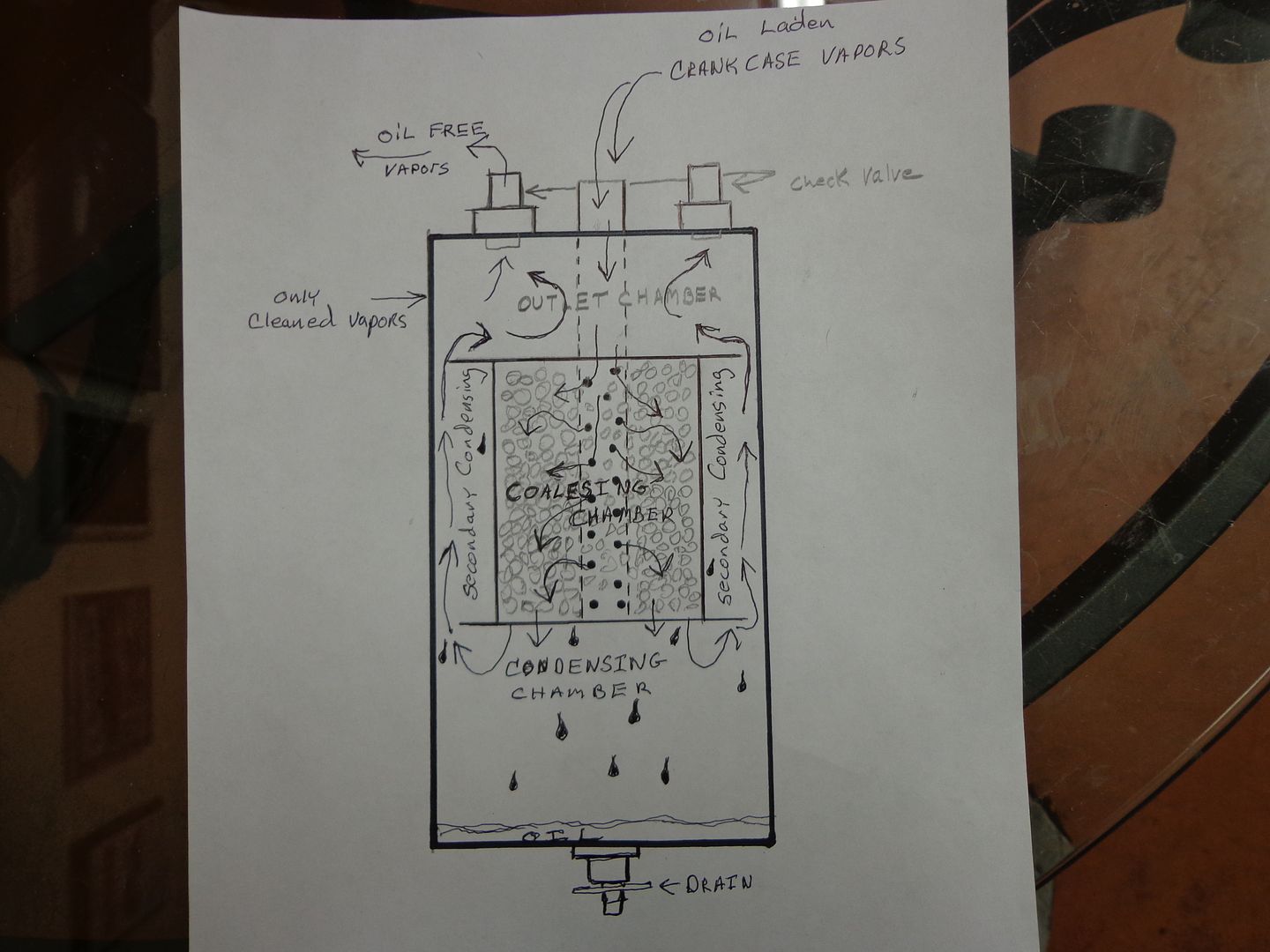

Here is a crude sketch to show:

Oil laden vapors enter the center and travel into the primary coalescing chamber (it is as big as many cans) where the perforated dispersion tube evenly distributes them through the coalescing media. This separates 90-95% of the mix. From there, the vapors exit the bottom and enter into the primary condensing and collection chamber. The final suspended liquids will coll and condense falling to the bottom for containment. The vapors then must pass a lower disc baffle that ensures even contact with the outer cooling wall and then into the secondary condensing chamber where the flow again slows to allow any left over droplets that have collected and condensed to fall from suspension before they again are forced past the upper disc baffle and into the separate outlet chamber where they again slow until pulled out either the primary outlet or secondary outlet.

over 7" between any oil laden vapors and the cleaned vapors, and 4 separate chambers and 3 separate steps. And anyone with any other brand can can easily test for pull through by adding a air compressor separator ($10) between any can and the intake vacuum to see how much most cans allow to be pulled right through them...no matter the brand name.

Hope this helps!